- Home

- Products

- Applications

- Capacitors ad Familiares Appliances

- Capacitors for Power Supple

- Capacitors ad DUXERIT Lighting

- Capacitores pro Mobile Et DSL Appliances

- Capacitores pro Automotive & Vehiculis

- Capacitores pro Photovoltaic Inverters

- Capacitors for Ventus Power Plantarum

- Capacitors pro Renewable Energy Systems

- Capacitors ad inductionem Heating

- Capacitors pro Medical Equipments

- Capacitors ad Industrial Imperium

- Capacitors for Power Electric

- Capacitors ad Rail Transit

- Capacitors pro Smart malesuada euismod

- Capacitors for University & Research Institute (High Energy Physics)

- De Us

- News

- Contact Us

-

- Capacitors ad Familiares Appliances

- Capacitors for Power Supple

- Capacitors ad DUXERIT Lighting

- Capacitores pro Mobile Et DSL Appliances

- Capacitores pro Automotive & Vehiculis

- Capacitores pro Photovoltaic Inverters

- Capacitors for Ventus Power Plantarum

- Capacitors pro Renewable Energy Systems

- Capacitors ad inductionem Heating

- Capacitors pro Medical Equipments

- Capacitors ad Industrial Imperium

- Capacitors for Power Electric

- Capacitors ad Rail Transit

- Capacitors pro Smart malesuada euismod

- Capacitors for University & Research Institute (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors ad Familiares Appliances

- Capacitors for Power Supple

- Capacitors ad DUXERIT Lighting

- Capacitores pro Mobile Et DSL Appliances

- Capacitores pro Automotive & Vehiculis

- Capacitores pro Photovoltaic Inverters

- Capacitors for Ventus Power Plantarum

- Capacitors pro Renewable Energy Systems

- Capacitors ad inductionem Heating

- Capacitors pro Medical Equipments

- Capacitors ad Industrial Imperium

- Capacitors for Power Electric

- Capacitors ad Rail Transit

- Capacitors pro Smart malesuada euismod

- Capacitors for University & Research Institute (High Energy Physics)

- De Us

- News

- Contact Us

Productum Quaerere

Lingua

Exitus Menu

Quid est DC-Link Capacitor ad PCB uti specifica sarcina et plumbum-de modum?

Quid est DC-Link Capacitor ad PCB uti specifica sarcina et plumbum-de modum?

In DC-Link Capacitor ad PCB Est maxime in DC circuits et suscipit key negotium de thesaurizantes et releasing electrica industria. In potestate electronic systems, in DC output de potentia copia non est specimen smooth DC, sed habet quaedam gradus in Rippele. Haec circulorum quasi undercurrents in circuitu, quod potest intermixti sensitivo electronic components et etiam afficiunt perficientur et stabilitatem totius ratio. Primarium responsibility de DC Link Capacitor est agere ut "intentione Regulator". Per suum præcipiens et dimissis processus, efficaciter smoothes hi subtilis, facit output DC intentione magis firmum et praebet pura et reliable potestate copia elit pro downstream circuitus.

Non solum autem, cum adversus instantanea mutationes in onus, ut motor incipiens, electronic apparatu switching operantes modus statim, etc., hodiernam demanda in circuitu erit mutare dramatically. In hoc tempore, in DC Link Capacitor potest Respondeo cito, dimittere vel absorbet electrica industria, ludere a buffering partes, vitare magnam voltage fluctuationes, in variis operationem in variis operantes potest. Momentum est sicut cor humani corporis, qui stabulantis continuously "industria sanguinem" ad totius Circuit ratio et maintains normalis operationem electronic apparatu.

Flamma, retardant plastic Crusta: tutam et solidae

Per operationem electronic apparatu, praesertim in aliqua application missionibus cum princeps virtutis et altum calorem generationem, in potentiale ignis periculo non neglecta. Semel ignis occurrit, non solum causa damnum ad apparatu, sed etiam gravi salutem accidentia, unde in casualitatibus et possessionem damna. Ideo ad key components ut DC Link Capacitors, Flamma retardant perficientur eorum crusta materiae est crucial.

In UL94 standard, as a globally recognized test standard for the combustion performance of plastic materials, provides an authoritative basis for evaluating the flame retardant ability of materials. Among them, the UL94 V-0 level represents extremely high flame retardant performance. Plastic materials that reach this level can respond quickly when facing flames, effectively prevent the spread of flames, and greatly reduce the possibility and degree of harm of fire.

In use of flame-retardant plastic shells that meet the UL94 V-0 standard is like putting on a solid "fireproof armor" for DC link capacitors. When the ambient temperature rises abnormally or even encounters open flames, this shell can delay the development of the fire with its own flame retardant properties, buying precious time for personnel evacuation and fire fighting. At the same time, it can also prevent the combustible materials inside the capacitor from contacting with external fire sources, cutting off the chain of fire occurrence from the source, and ensuring that the entire electronic equipment operates in a safe environment.

Praeterea, flamma-retardant plastic testa etiam habet bonum mechanica et velit proprietatibus. Potest providere certa corporalis praesidio ad delicata structuram intra capacitor resistere externa mechanica accentus ut collisionem et vibrationem et ne internum components a esse laedantur. Simul electrica velit obice efficaciter prohibet vena leakage, ensures electrica salus apparatu, et dat DC Link CAPACITER ad opus stabiliter in complexu electrica elit.

Epoxy resinae signantes: a seamless obice cum agentibus tutela

In the use environment of many electronic devices, there are often various unfavorable factors, such as humid air, corrosive gases, dust particles, etc. These factors are like "invisible killers" of electronic components, which may gradually erode the internal structure of the capacitor, resulting in performance degradation and even causing faults such as short circuits. Ut obviam his challenges, epoxy resinae signa technology venit in esse et factus solidum linea defensionis praesidio DC Link Capacitors.

Epoxy resinae est thermosetting resina quod potest formare summus viribus, summus stabilitate solidum materia per chemica reagens cum certis curing agente. Hoc ostensum multis praestantes commoda in signationem applicationem de DC Link Capacitors.

Epoxy resinae est optimum IMPERVIUS perficientur. Speciali coetus in suum mocecular structuram potest formare stricta eget vincula cum aqua moleculis, efficaciter claudebant penetrationem humorem. In a humid environment, whether it is an industrial workshop with high humidity or outdoor electronic equipment that may be attacked by rain, DC link capacitors sealed with epoxy resin can be safe and sound, and the internal components will not short-circuit or corrode due to moisture, ensuring the reliable operation of the equipment under harsh humidity conditions.

Etiam habet bonum signantes. Per curandum processus, epoxy resinae potest perfecte replete minima hiatus et evacuat intra capacitor habitationi formare seamless signantes layer. Hoc non solum impedit intrusionem humorem, sed etiam efficaciter cuneat ingressum de aliis pollutants sicut pulvis et mordax vapores. Etiam in pulveris Factory ambitus vel loca ubi est periculum chemical corrosio, in interiorem capacitor potest semper manet mundus et siccum, vitandum perficientur degradationem fecit per congeriem pollutantium.

Epoxy resina habet fortis tolerantia variis eget substantias ut acida, alkalis et sales. In aliqua electronic apparatu in eget, electroplating et alia industries, variis corrosive chemicals potest esse in circuitu environment. In epoxy resinae signantes layer de DC Link Capacitor potest resistere exesa horum oeconomiae sicut solidum scutum, ne metallum partes et internum circuits de capacititor et ensuring, ita extendens in ministerium vitae in capacitor et pergratum eget elit.

Et fortis vinculum vis etiam a major utilitatem. Epoxy resinae potest esse arcte vinculum ad externum testa materia de capacitor et superficies internum components formare fortis nexu. This reliable bonding not only enhances the stability of the seal, but also improves the mechanical strength of the entire capacitor structure, enabling it to better cope with mechanical stresses such as vibration and impact, ensuring that the internal components of the capacitor will not be displaced or damaged in various harsh mechanical environments, and maintaining the normal working state of the equipment.

Tinned aeris terminum plumbum-sicco: praestet optimum electrica nexu

DC Link Capacitorors postulo ut constituere certa electrica hospites cum aliis components in circuitu ad consequi lenis traductionem et distributionem electrica industria. Sicut electrica ducunt, de terminatio capacitor, tinnulatur aeris terminatio ludit a key munus in hoc processus. Et unique perficientur proprietates providere solidum praestet pro efficient et firmum electrica hospites.

Aeris, quod est optimum PROLIXUS materia, quae maxime humilis resistentibus. Hoc quod cum vena per aeris terminatio, potest esse leniter traducitur valde resistentia, ita valde reducendo amissio electrica industria in transmissione processus. Comparari cum aliis materiae cum pauperem conductivity, usum aeris terminals potest significantly amplio industria utendo efficientiam de circuitu et reducere necesse industria perditio. In aliqua application missionibus cum maxime princeps requisitis ad industria efficientiam, ut electrica coegi ratio of novus industria vehicles et summus efficientiam potentia modules de notitia centers, utilitatem de industria, salvis operationem in armorum.

Ut amplius amplio perficientur et reliability of aeris terminals, tenui iacuit de stagnum solet patella in superficiem. In tinning processus multiplex beneficia. Tin habet bonum oxidatio resistentia et potest formare a densa cadmiae tutela amet super superficiem aeris terminum, efficaciter ne aeris a chemica reagens cum oxygeni in aere, ita aera oxidatio et rufus. Hoc non solum se extendit ministerium vitae terminationis, sed etiam per longum-term stabilitas electrica nexu. Quia semel in superficies aeris terminatio est oxidized, ejus resistentia erit crescat, unde in decrementum in efficientiam potentiae transmissione, et etiam causa problems ut bene ne haec casus fiat.

In tin plating layer can also improve the solderability of the terminal. When the DC link capacitor is installed on the PCB board, it is usually necessary to achieve electrical connection by welding. The tinned copper terminal can better blend with the solder to form a firm and reliable solder joint. This makes the welding process easier to operate, the welding quality is more stable, and the risk of electrical failure caused by poor welding is reduced. In the large-scale production of electronic equipment, good solderability can improve production efficiency, reduce production costs, and ensure the consistency of product quality.

Tin-patella aeris terminals etiam habent bonum mechanica vires et corrosio resistentia. In usum electronic apparatu, terminals potest esse subiecta variis mechanica passiones, ut plugging et unplugging, vibrationis, etc. et laedatur in mechanica viribus sine facili et laedatur, cursus reliability et in proprio et laedatur, cursus reliability de electrica nexu. In eodem tempore, in aliquo ambitus cum mordax vapores aut liquida, stagnamque iacuit potest providere additional praesidium ad aeris terminals, resistite corrosio, ut terminales potest adhuc opus est Northmannice inter capacitor et tenere ad stabile electrica nexu inter capacitor et tenere ad stabile electrica nexu inter capacitor et tenere ad stabile electrica nexu inter capacitor et in circuitu.

Comprehendo commoda: Synergy creates optimum perficientur

In DC link capacitor adopts a combination design of flame-retardant plastic shell, epoxy resin sealing and tinned copper terminal lead-out. It is not a simple stacking of components, but the various parts work together and complement each other, laying a solid foundation for the excellent performance and reliable operation of the capacitor.

In flame-retardant plastic shell provides key safety protection, effectively reduces the risk of fire, and creates good conditions for the safe operation of the entire electronic equipment. At the same time, as the external protection structure of the capacitor, it provides a stable physical environment for the internal components to resist external mechanical shock and environmental interference. Epoxy resin sealing further strengthens the protection of internal components. Through efficient waterproof, dustproof and anti-corrosion performance, it ensures that the inside of the capacitor is always in an ideal working state and is not affected by external harsh environmental factors. Tinned copper terminal lead-out focuses on achieving excellent electrical connection, with low resistance and high stability, ensuring efficient and reliable transmission of electric energy between the capacitor and the circuit.

Cum haec tria sunt organice combined, in synergistic effectum produci enables DC Link Capacitors praestare bene in variis complexu application missionibus. In agro Industrial automation, adversus dura environment of caliditas, princeps humiditas, pulvis et fortis electromagneticorum intercessiones, et flamma-retardant in complexu resistere environmental electrica in complexu in universa electrica operationem in automation apparatibus. In altilium administratione ratio et motor coegi ratio of novus industria vehicles, in perficientur et reliability de capacitors sunt maxime princeps. Hoc combination consilio potest obviam necessitatibus firmum repono et celeri release of Electric industria sub conditionibus ut summus celeritas incessus et crebris satus-subsisto, cum cursus electrica salutem.

Ex consilio prospectu, quod combination consilio plene considerat variis challenges quod electronic apparatu ut faciem in diversis application missionibus, et comprehendendo optimizes key factores ut salus, et comprehendendo key factors ut salus, et electrica perficientur. Non solum amplio perficientur et reliability de DC Link Capacitor ipsum, sed etiam auget firmitatem, diuturnitatem et salus electronic apparatu ut totum. Cum continua progressionem electronic technology, in perficientur ad electronic components sunt magis magisque restrictius. Hoc diligenter disposito et verificatur combination solutam dubio praebet fortis praestat pro DC Link Capacitors ad PCBBs ad permanere ludere a key munus in posterum complex applications, et fit in altiorem perficientur progressionem de electronic apparatu versus altius in promovendos et magis certiores directionem.

RECOMMENDED PRODUCTS

-

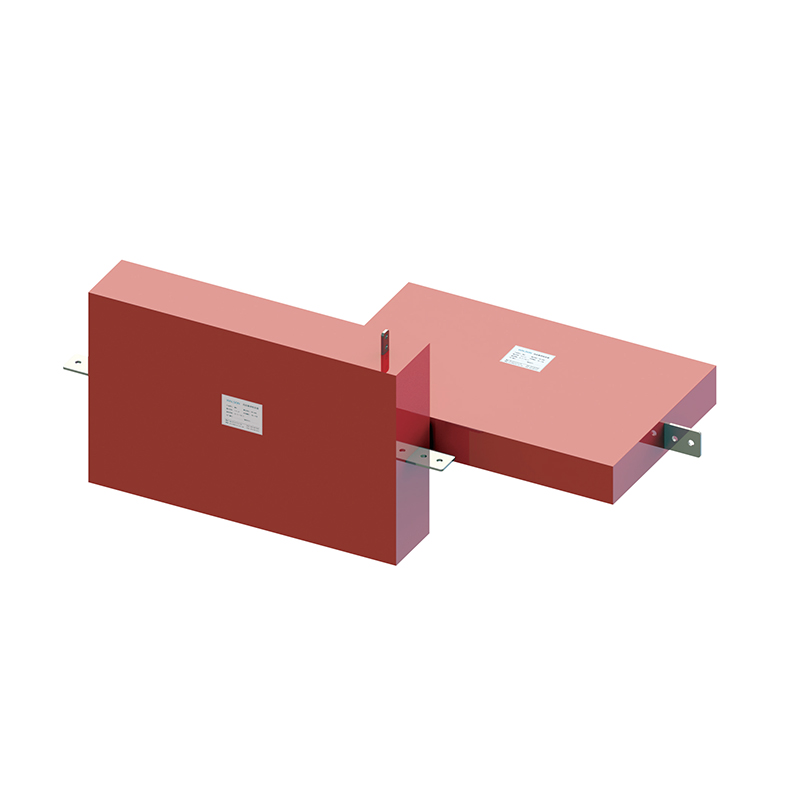

WPH seires High intentione Pulsus Capacitor

Features: Insulae habitationi, genus sicco ... View More

-

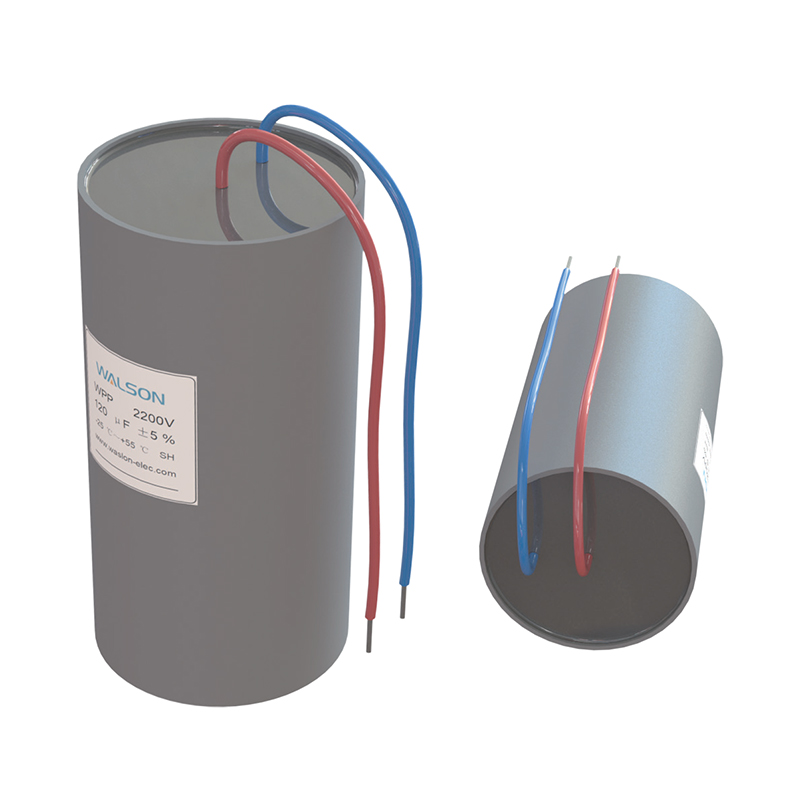

WPP series metallized Polypropylene film Pulsus Capacitor

Features: Arida encapsulata casu plastico cyli... View More

-

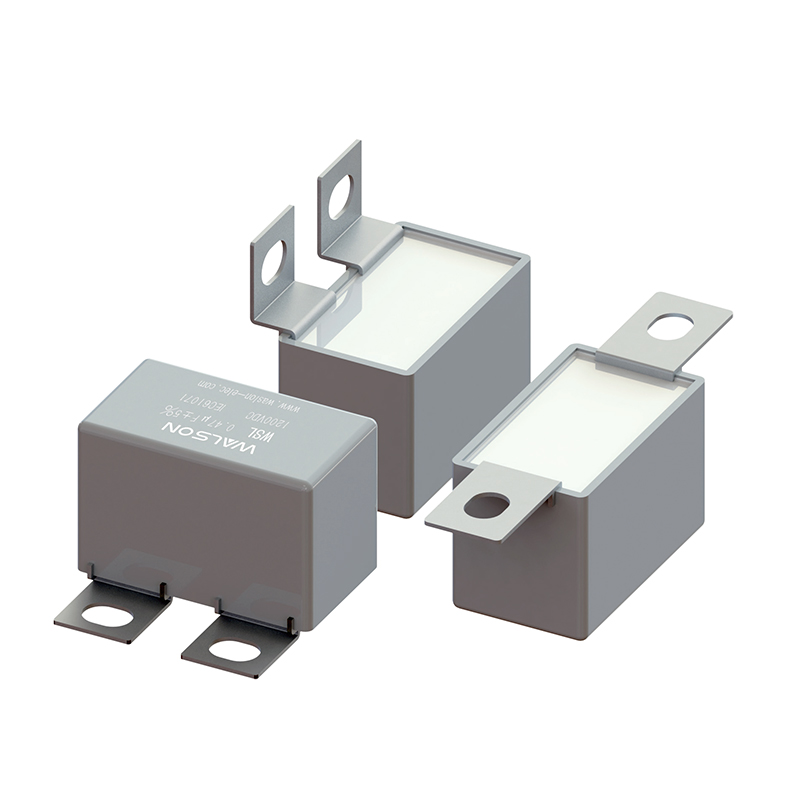

Series Snubber Capacitor pro IGBT (Lug Terminals)

Features: Summus temperatus resistens PP cinem... View More

-

Erat series signatus Singulus/Tres Phase AC Filter Capacitor

Features: Metallized polypropylene film magna ... View More

- Oratio : N. XXII, Xingye Road, Changjing oppidum, Jiangyin, Wuxi urbem, Jiangsu provinciae

- Zip code: 214104

- Phone: +86 – 138 1203 1188

- Tel : +86 - 0510 - 88719928 - 805

- Fax : +86 - 0510 - 88719928

- Inscriptio: [email protected] / [email protected]

- Home

- Products

- Applications

- Capacitors ad Familiares Appliances

- Capacitors for Power Supple

- Capacitors ad DUXERIT Lighting

- Capacitores pro Mobile Et DSL Appliances

- Capacitores pro Automotive & Vehiculis

- Capacitores pro Photovoltaic Inverters

- Capacitors for Ventus Power Plantarum

- Capacitors pro Renewable Energy Systems

- Capacitors ad inductionem Heating

- Capacitors pro Medical Equipments

- Capacitors ad Industrial Imperium

- Capacitors for Power Electric

- Capacitors ad Rail Transit

- Capacitors pro Smart malesuada euismod

- Capacitors for University & Research Institute (High Energy Physics)

- De Us

- News

- Contact Us

Copyright © Wuxi Walson Electronics Co., Ltd. Metallized film Capacitor Sinis Manufacturers